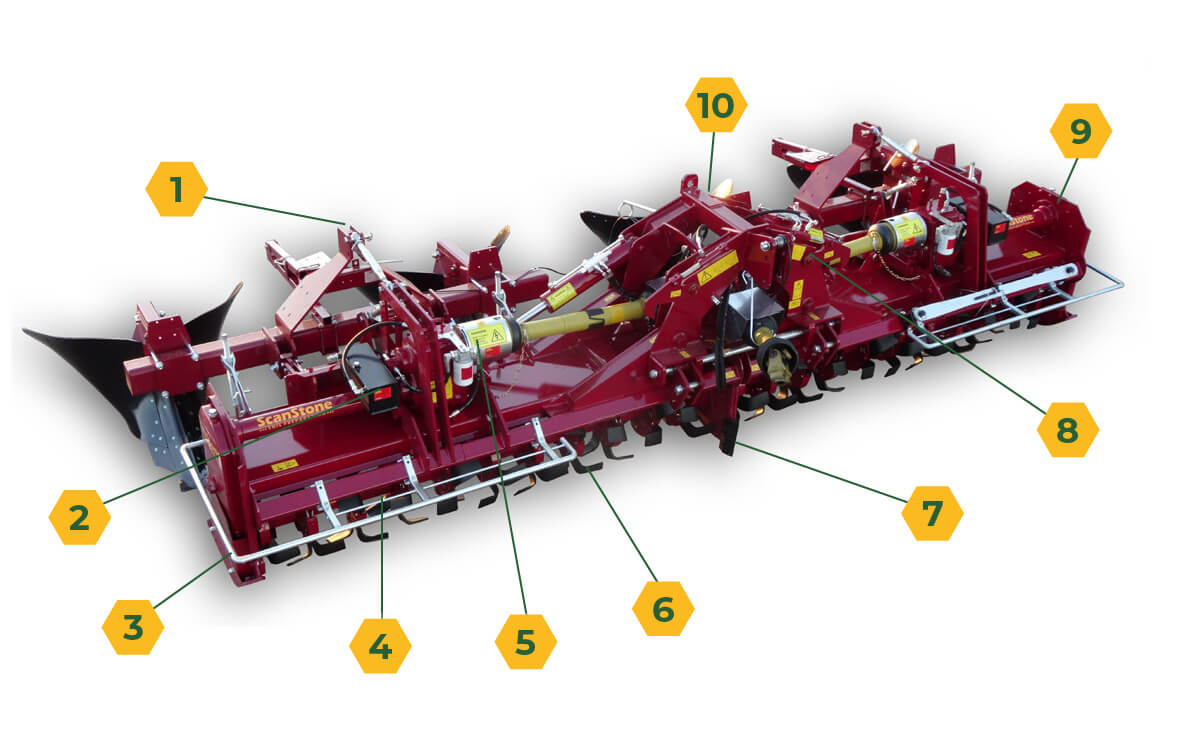

In heavier soil types or lay ground, the bed tilling process can be appropriate. The ScanStone bed tiller is an efficient and effective machine, primarily due to having quick change blades. Depending on the rotor speed, the bed tiller can do a very fine job or a rougher job depending on how much fuel and energy the farmer wishes to use. The amount of bed tilling should be proportional to the forward speed of the destoner.

Quick Change Blades

The Quick Change Blade System works with a double flange rotor, locating bolts, and a clip and pin which holds the blade securely. This is a cost-effective system, because the holding bolts and the clip and pin do not need replaced every time you change a blade, unlike a bolted blade where you have to buy 2 bolts and 2 nuts every blade change. It is extremely rare that blades are lost with this system because the hard pin and clip never come off. The flanges are protected by hardened steel wear plates which are reversible and replaceable.

CHANGING BLADES WHILE FUELLING UP

‘The ScanStone quick change blade system allowed changing of blades in morning while fuelling up. The ScanStone Triple Bed Tiller has proved a reliable and worthwhile machine over the last 3 years. Reducing wear on the destoners was one of the key advantages of the bed tiller. We completed around 2000 acres tilling both on the plough surface as well as into opened beds.’

- Option of classic or chateau-style ploughs mounted on independent frame with depth and pitch adjustment

- Reduction gearboxes oil coolers

- Underside replaceable wear strip

- Suitable distance between rotor and hood to reduce wearing on blades and blocking up underneath

- Automatic CAM style safety clutches

- Award winning quick change blades (with tightening system)

- Heavy duty centre share with replaceable blades

- Reduction gearboxes reducing torque strain on machine and shafts

- Chain free end gearboxes with heavy duty gears

- Centre gearbox oil cooler option