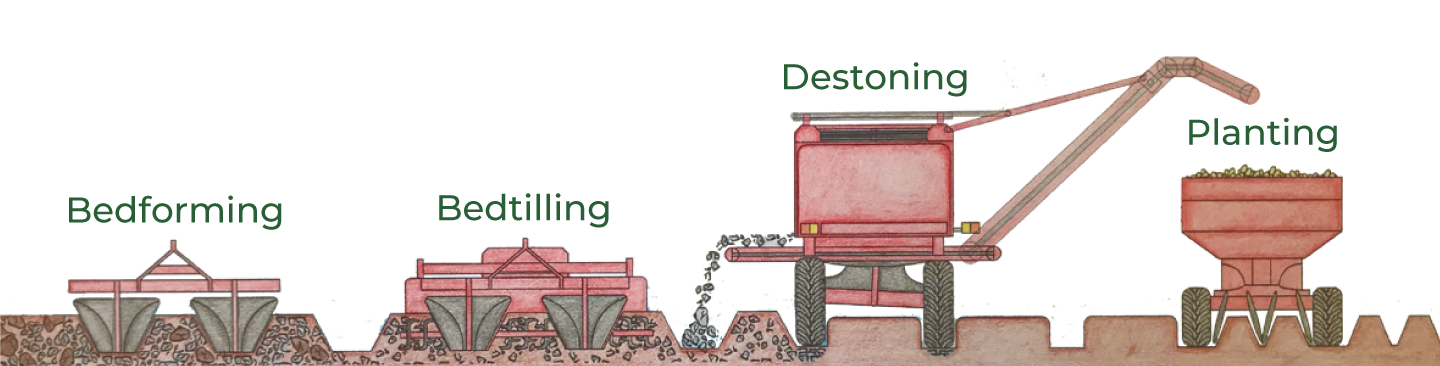

The most important aspect of growing high-quality potatoes is ensuring that the soil has been properly prepared prior to planting. In order to improve crop quality and yield, it is essential to remove stones and large clods, while maintaining a healthy soil structure. Not only does this reduce damage on the harvested crop and wear on the harvesting/grading machinery, but it also gives the tractor and trailers traction at harvest time, as the stone is situated under the tyres and away from the plantation bed.

Bedformers

The bed maker is designed to go into pre-cultivated ground, both to create beds for destoning and aeriating the soil. It is key for the bed maker to get as much soil as possible out of the trench and into the bed. This gives the destoner the maximum potential.

Bedtillers

In heavier soil types or lay ground, the bed tilling process can be appropriate. The ScanStone bed tiller is an efficient and effective machine, primarily due to having quick change blades. Depending on the rotor speed, the bed tiller can do a very fine job or a rougher job depending on how much fuel and energy the farmer wishes to use. The amount of bed tilling should be proportional to the forward speed of the destoner.

Destoners

Destoners largely cultivate to a depth of between 10 and 18 inches. This means that it can produce a graded amount of soil to these depths. All the clods, stones and soil goes into the front of the destoner through an intake web. The choice of web pitch, or star configuration will depend firstly on the forward speed of the machine, the quality of the graded soil and the depth of the finished bed. Using webs to destone will always give a consistent grade of soil, however output can be limited if ground is wet or full of grass fibre. The star system is slightly more complicated to operate, whereby the finished bed is changeable, subject to the forward speed of the machine, the RPM speed of the tractor and the amount of soil in the machine at any one time. The stars generally perform well in grassy conditions, wet sandy conditions or heavy clay conditions.

Elevator

The top part of the elevator is a goose-neck and is able to be controlled up and down with hydraulics. The width and height of the flights are now adequate to carry a large capacity of stone up the elevator. The discharge point is directly in the centre of the second bed, meaning that a cart or trailer can be filled easily without the need for the trailer or tractor to be running on separated beds. This means two things; The trailer tractor is running on a hard surface and not in soft ground, and the separated beds are left undisturbed should the potato planting process follow on immediately afterwards.

Control Box

The dealer or service manager can access the advanced settings to adjust options such as the oil flow and setting up a new attachment such as stone box or elevator.

You can see how many hours the machine has done, and you can save and reset 2 trips. You can see the main info on the machine, such as serial number, year of manufacture and model number.

Testimonials

William and Alison Skea from ScanStone visited Fairlie Fresh, to see James Fairlie and his father Ian, and find out how they got on with their 2 new 5 Webber destoners after an uninterrupted season.