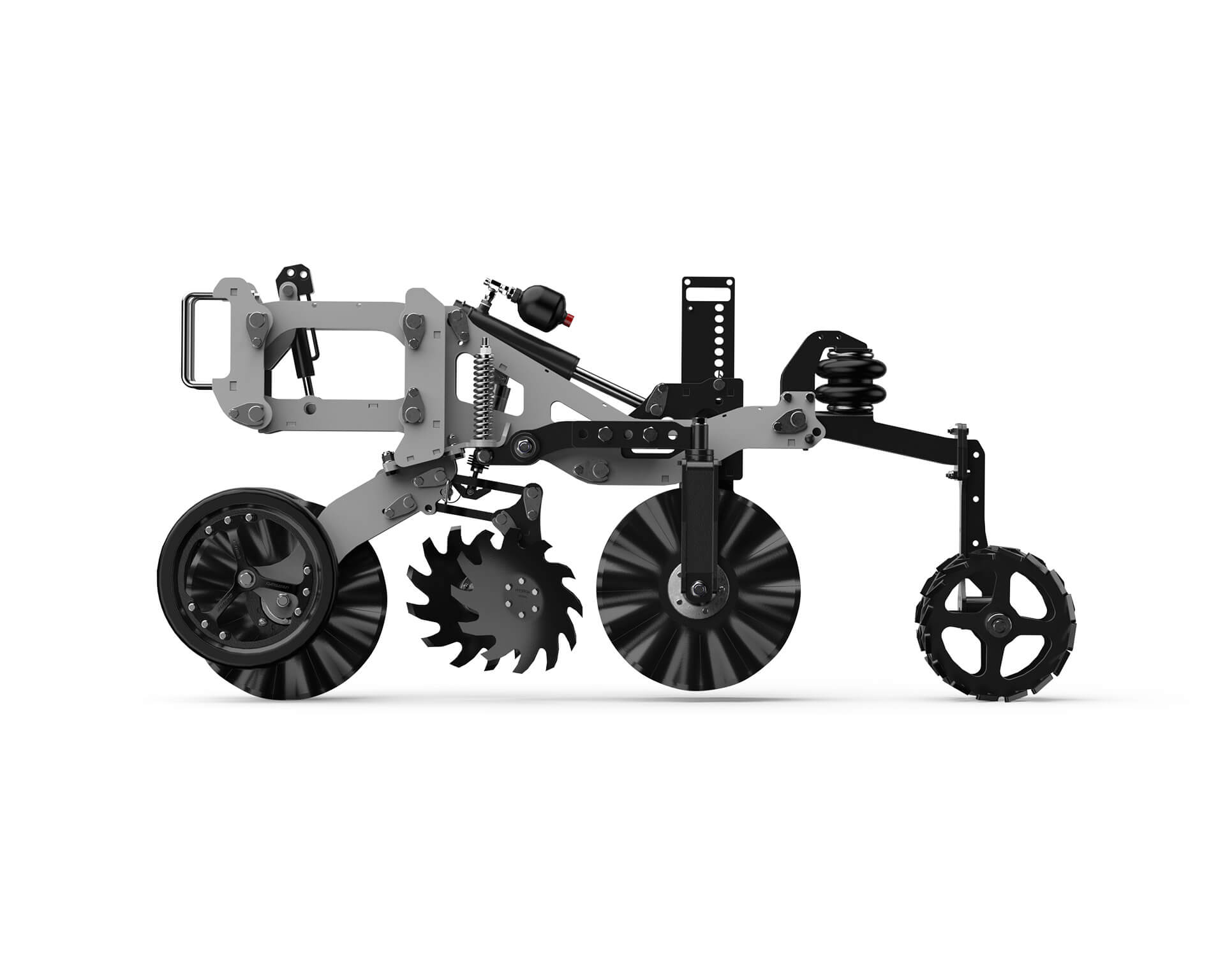

The Horizon SPX strip-till system combines the process of conventional tillage with the soil-protecting advantages of no-till by disturbing only the portion of the soil that is to contain the seed row.

Why choose the Horizon SPX?

- Horizon Agriculture possess over 15 years experience successfully applying strip tillage practices all over the world. With this wealth of knowledge, the Horizon SPX has been carefully designed with the ability to easily adapt to different applications and conditions.

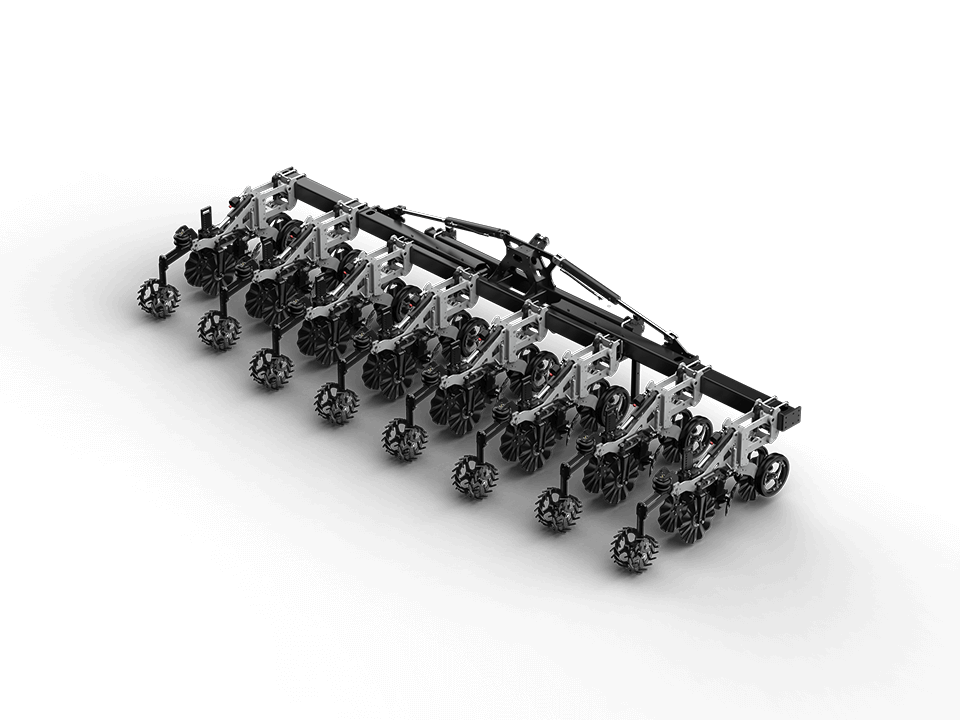

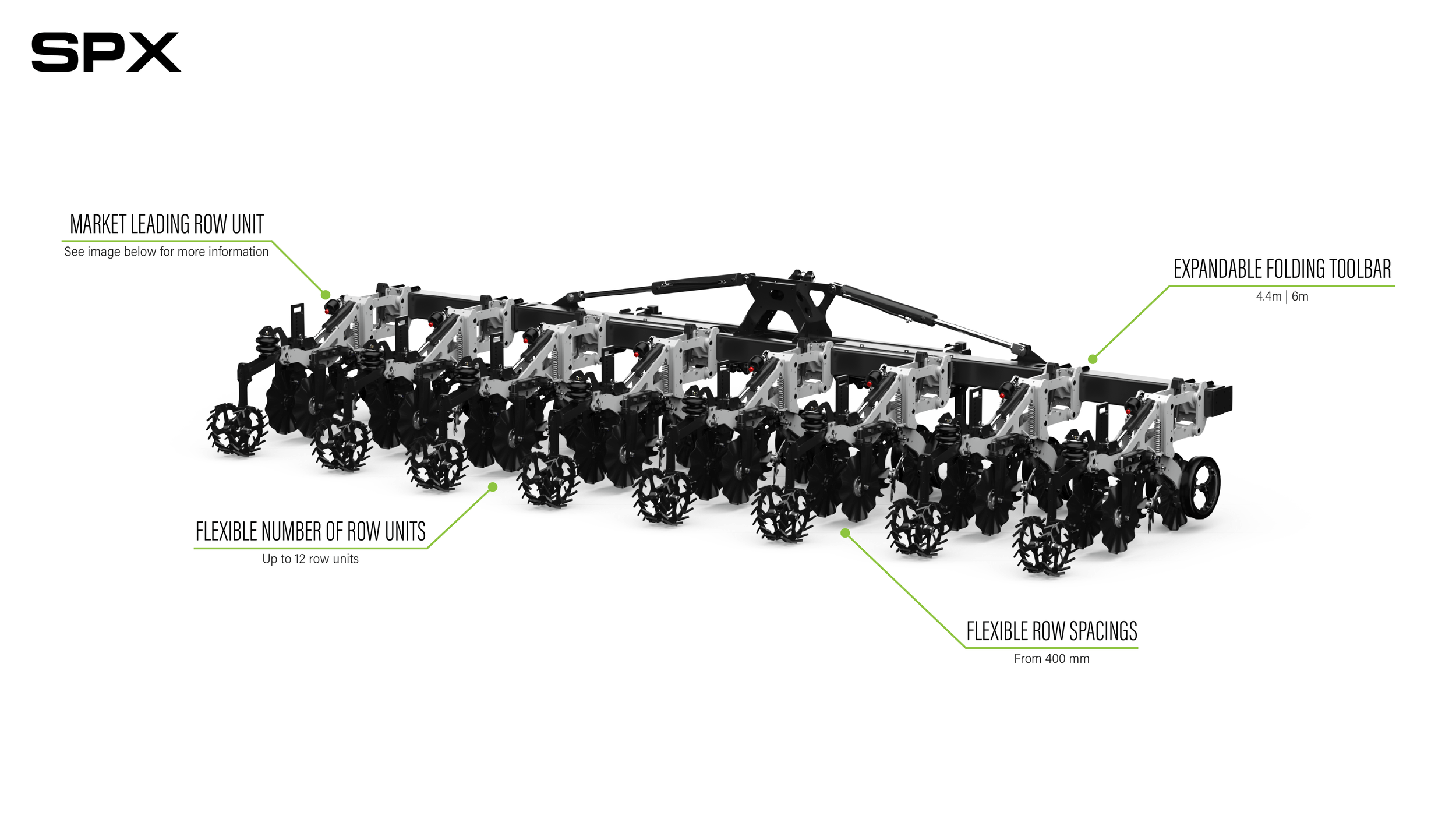

- The mounted toolbar is directly attached to the tractor’s 3-point linkage, allowing the SPX to perfectly follow the GPS which is essential for planter operations.

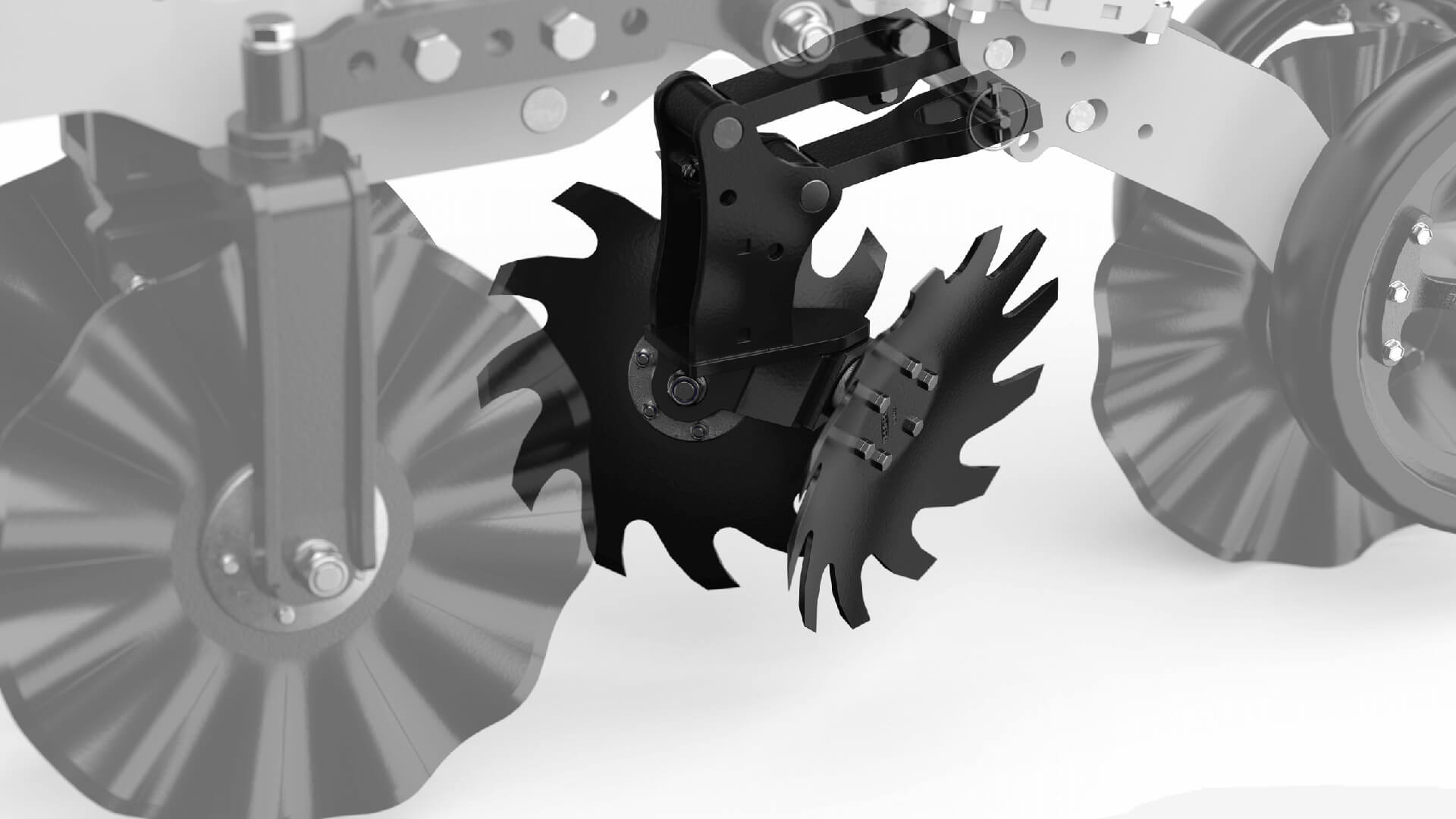

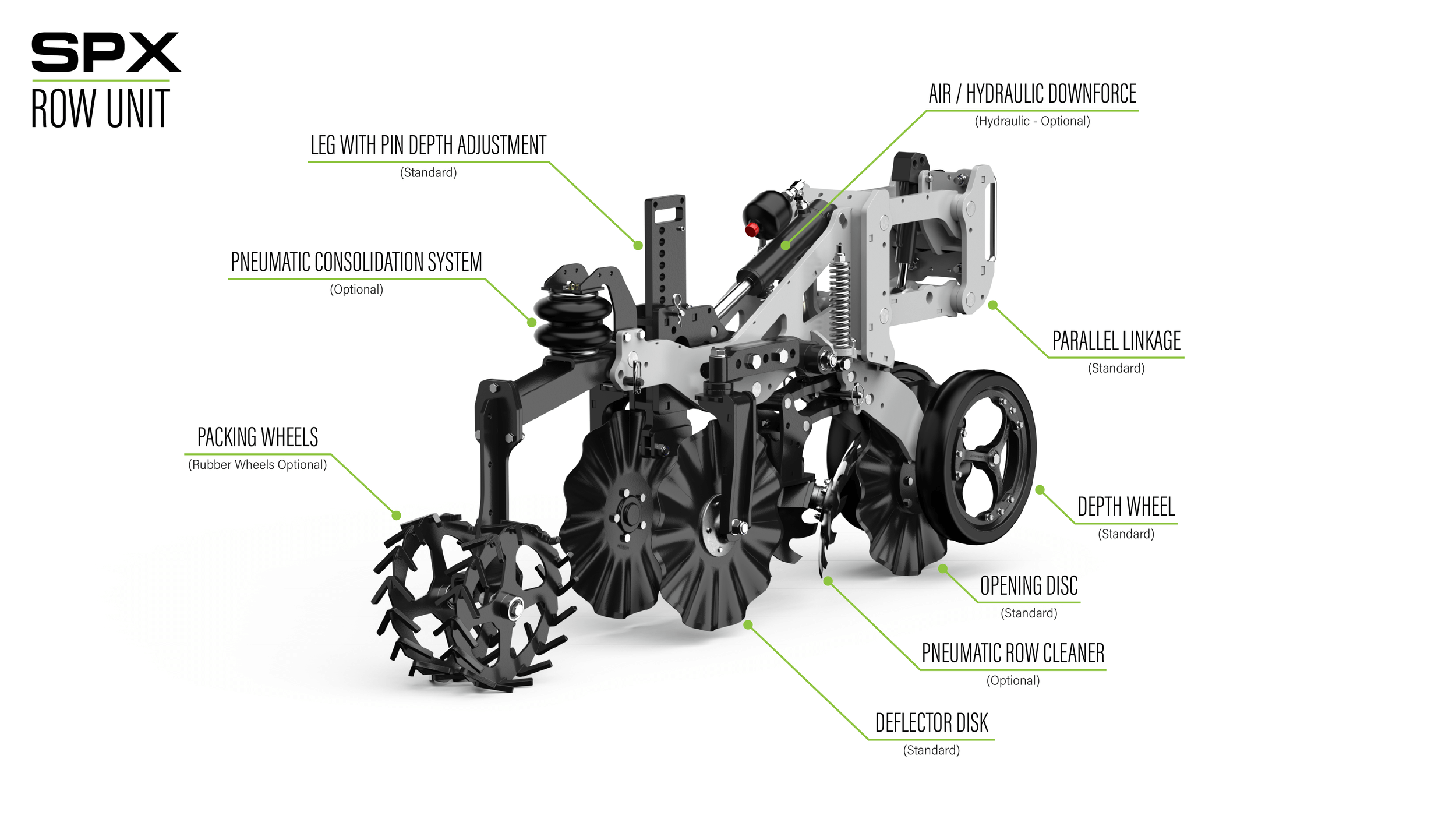

- Pneumatically controlled row cleaners with CleanSweep technology can be adjusted in-cab for quick and accurate adjustment.

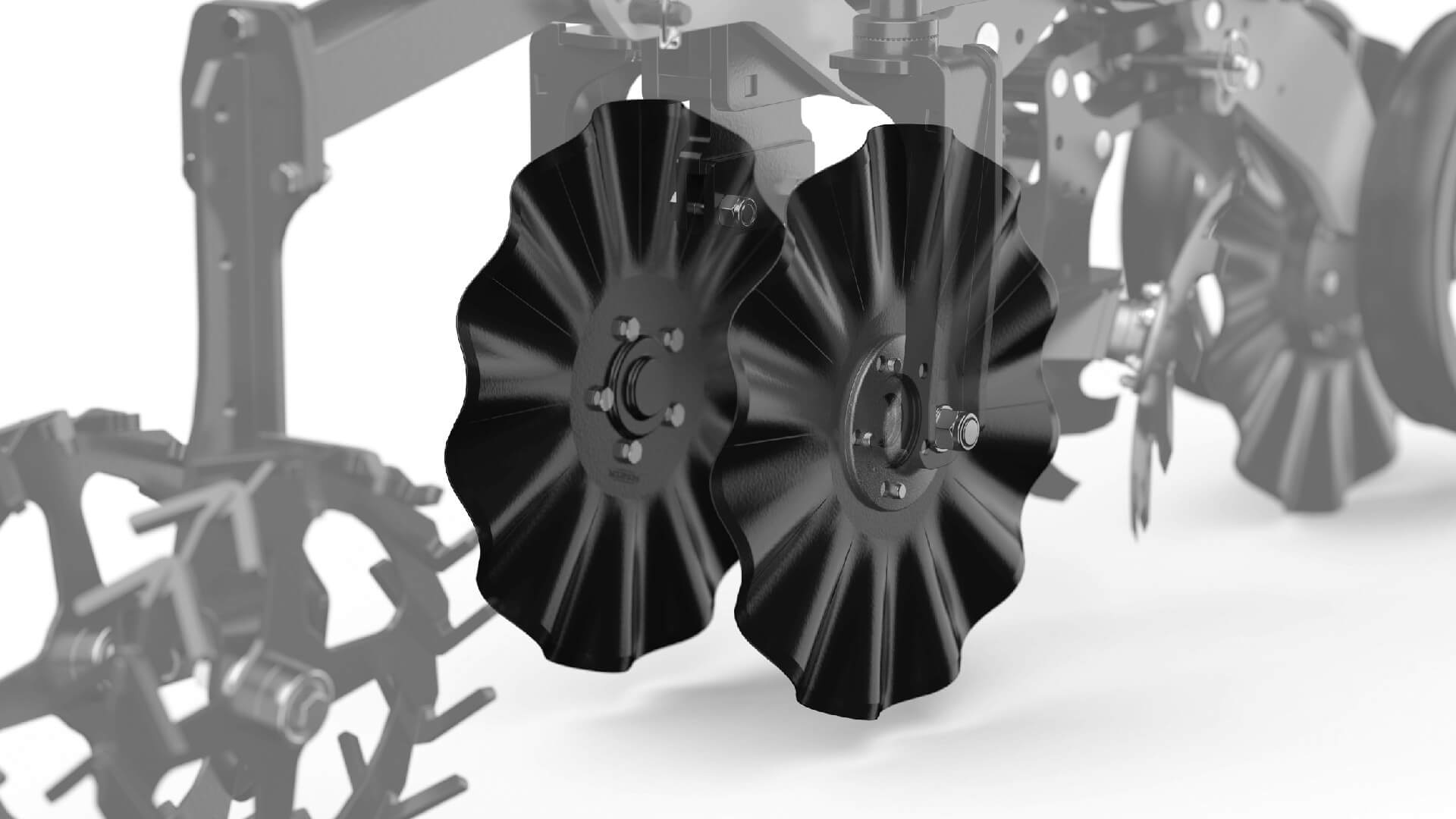

- The positioning, widths and angles of the deflector discs can be easily adjusted offering multiple berm building options.

- The pneumatic consolidation system with in-cab adjustment offers different wheel options for different soil types.

How does strip tillage work?

Strip tillage is a low disturbance, targeted tillage approach, consisting of only cultivating a narrow band of soil in which the crop is to be planted. This leaves lanes of uncultivated soil and residue on either side of the tilled strips over approximately two-thirds of the field surface.

Leaving these areas of undisturbed residue between the tilled planting strips is an excellent way to reduce risks of erosion, improve soil structure, enhance soil health and provide more stable footing for farm equipment.

For farmers with soils that are too challenging for a no-till system, strip tillage helps to allow farmers to break the soil up and alleviate compaction with a minimal effect on the microorganisms and other organic matter in the soil.

SPX strip-till features

Depth

The SPX can be operated to a depth of 40cm if required, however, in normal conditions, a depth of 15cm to 23cm is typical. A consideration when setting up the machine is that for every 5cm of depth, the draught force needed to pull the legs through the ground almost doubles, as well as increasing fuel consumption.

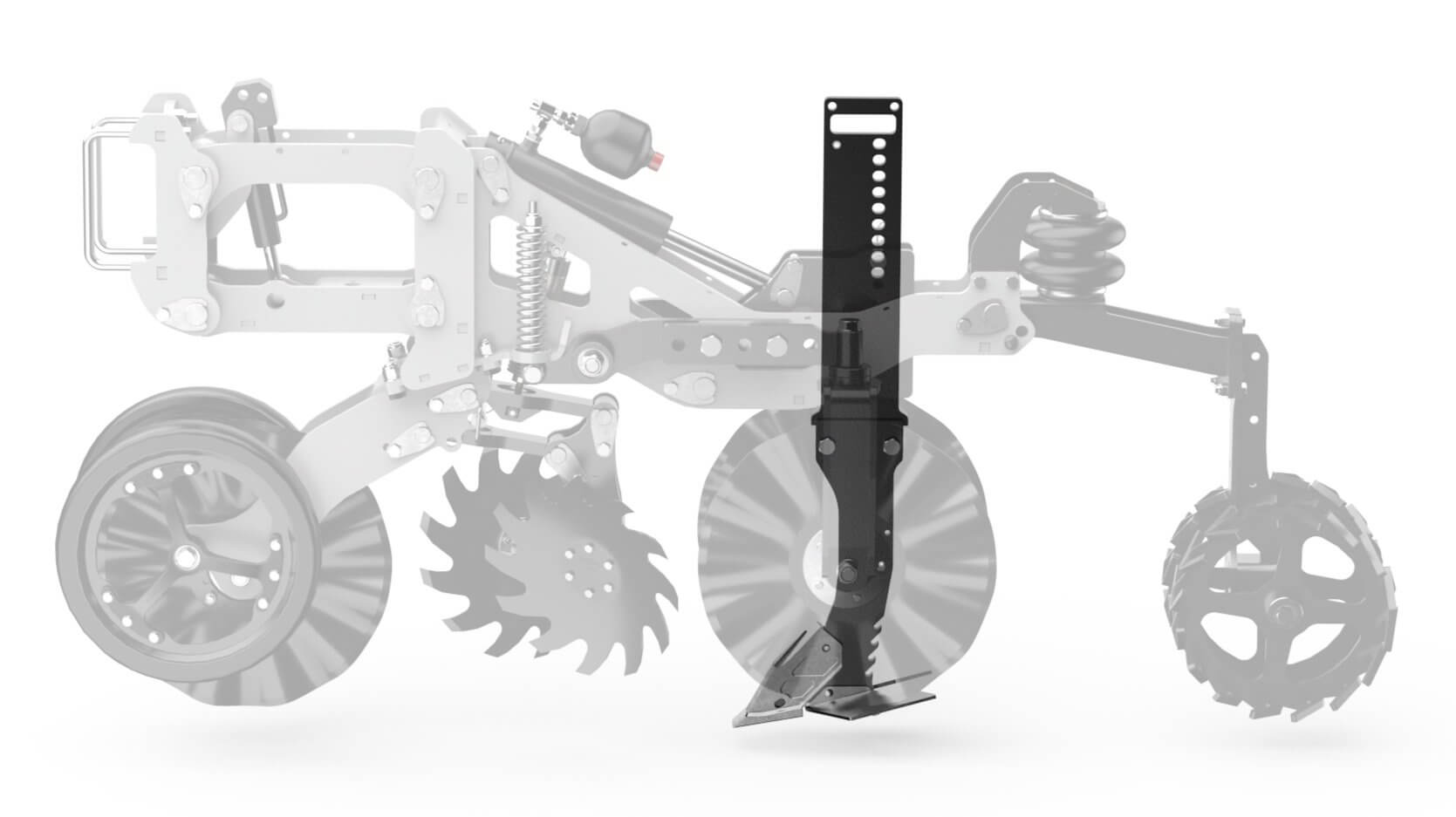

Tine

The tine assembly consists of the leg, shank, point and wing. Its purpose is to remove any compaction layers, move & fracture the soil, and place fertilizer accurately in the seeding zone (if fitted). Low and high disturbance points, along with medium (130mm) and wide (160mm) wings are available to manage soil movement and lift.